247 Knowledge Hub: The only industrial data platform you need

Use your machine data for

real innovation

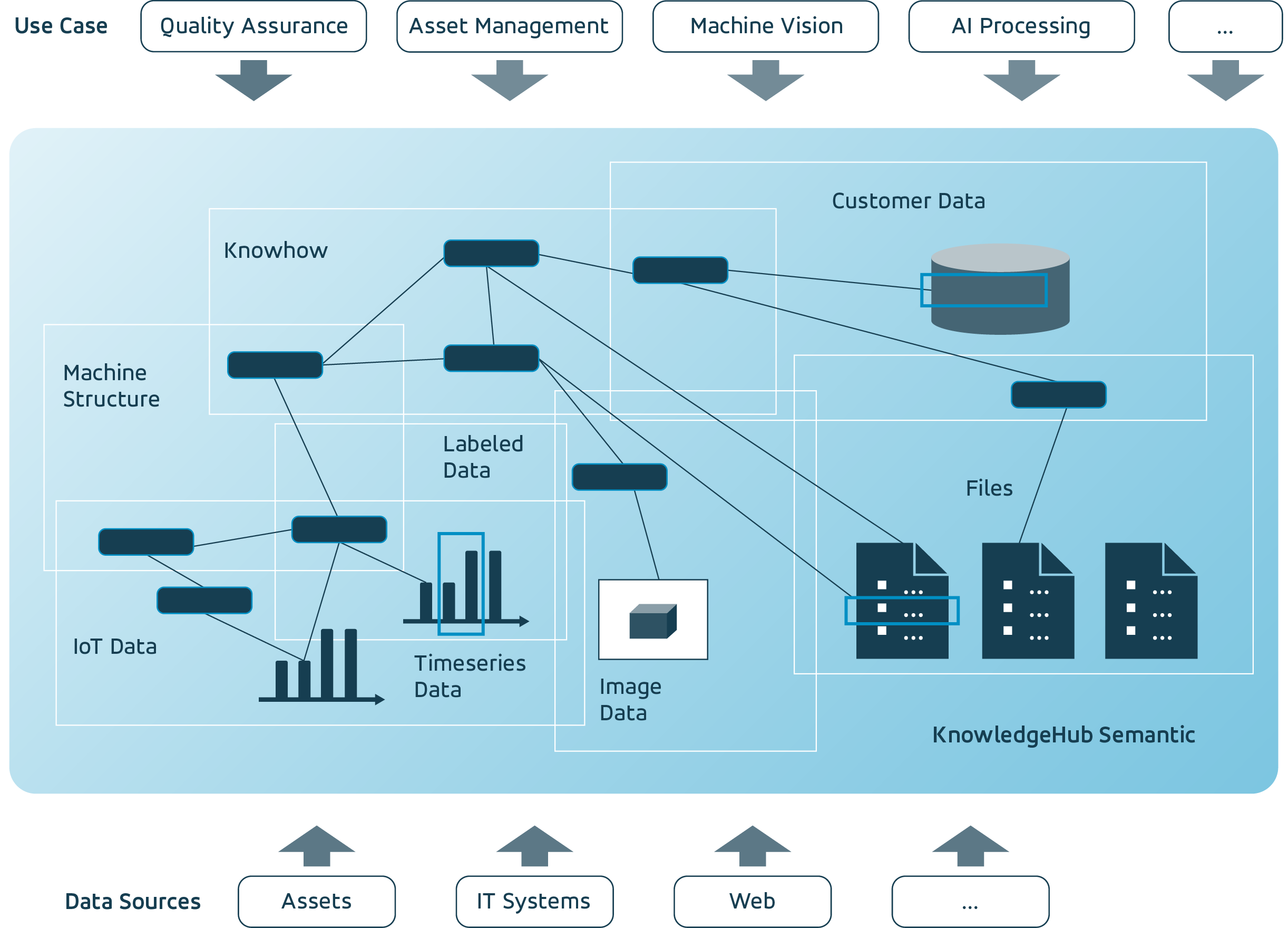

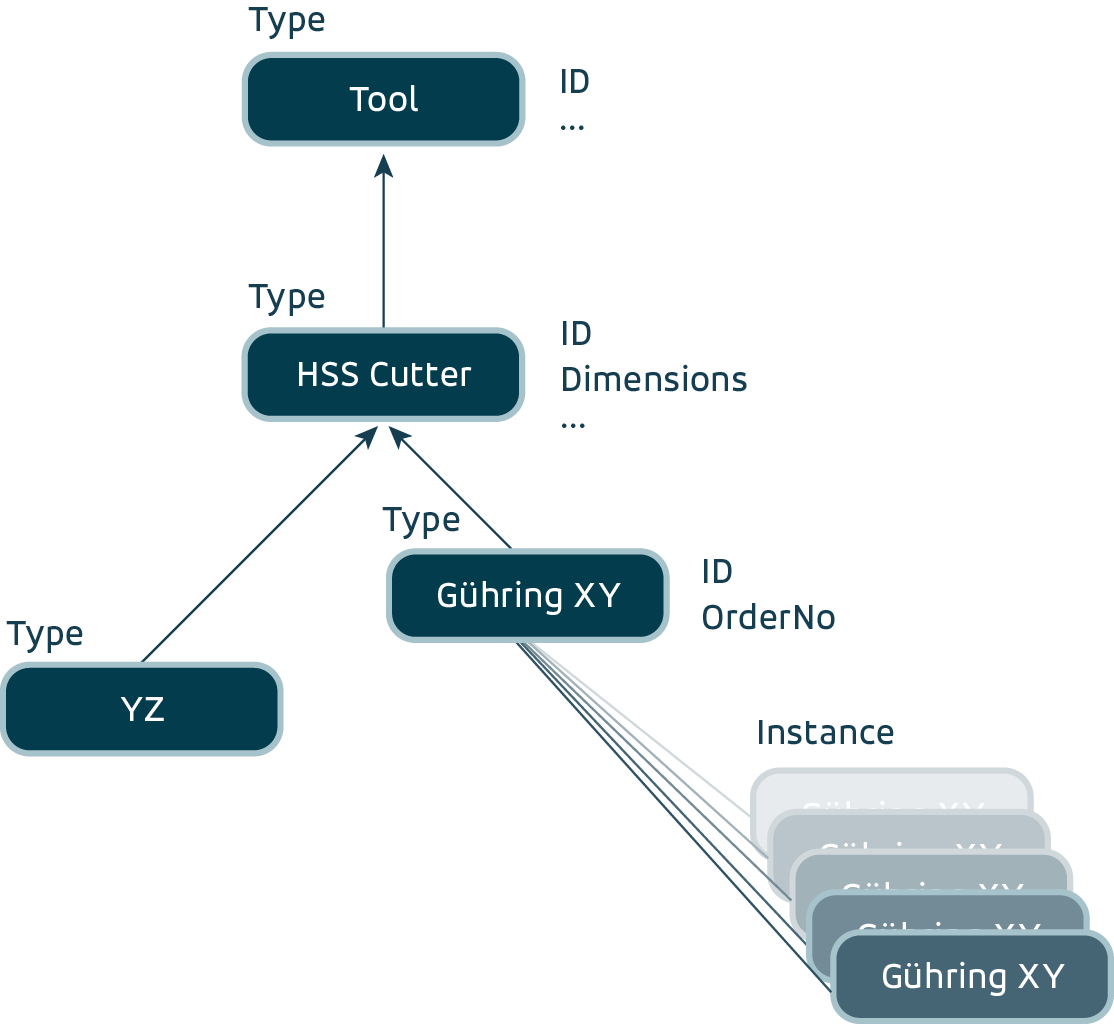

- Full control: collect all relevant machine data in one place for an unlimited period of time

- The ideal basis for AI-driven business models: offer future-proof digital services and inspire customers

- Smooth machine operation: increase efficiency and avoid downtime through digital enrichment with expert knowledge

- The modular system for industry: quickly ready for use, scalable and cost-effective – no programming knowledge required!

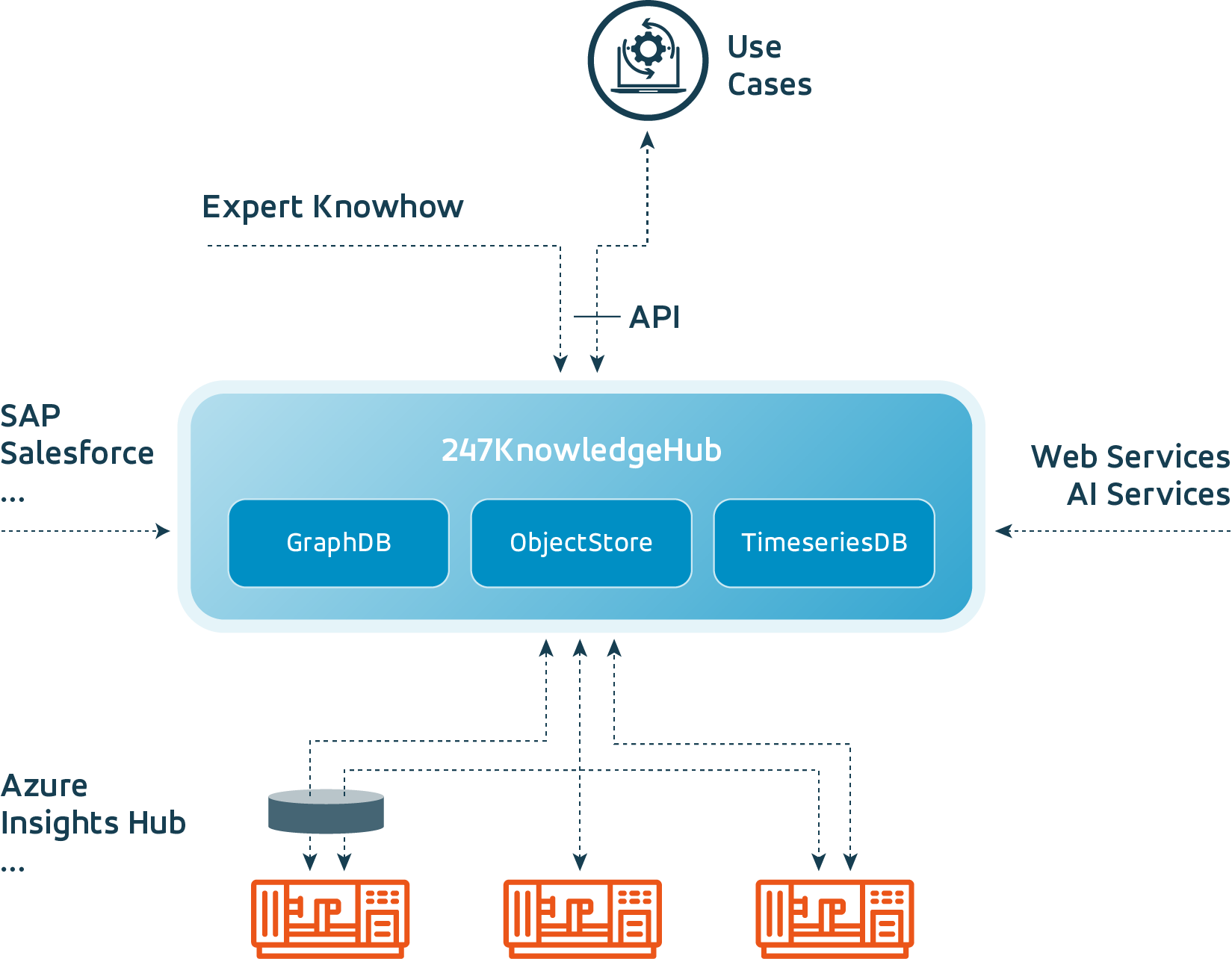

Seamless integration into your existing digital landscape:

- Interfaces: SAP, Salesforce, OPC UA, Excel

- Data integration: IoT data, time series data, CAD data, images, documents, files, videos

- Cloud integration: Azure, AWS, Google Cloud, Insights Hub (MindSphere), Bosch IoT Suite, CtrX

…and many more!

Data- and AI-based business models

for medium-sized machine and plant manufacturers and factory operators.

Data- and AI-based business models

for medium-sized machine and plant manufacturers and factory operators.

Get more out of your machine data

247KnowledgeHub is the optimal data Integration Platform for the industry. Scalable, easy to use and with your strategic interests at heart.

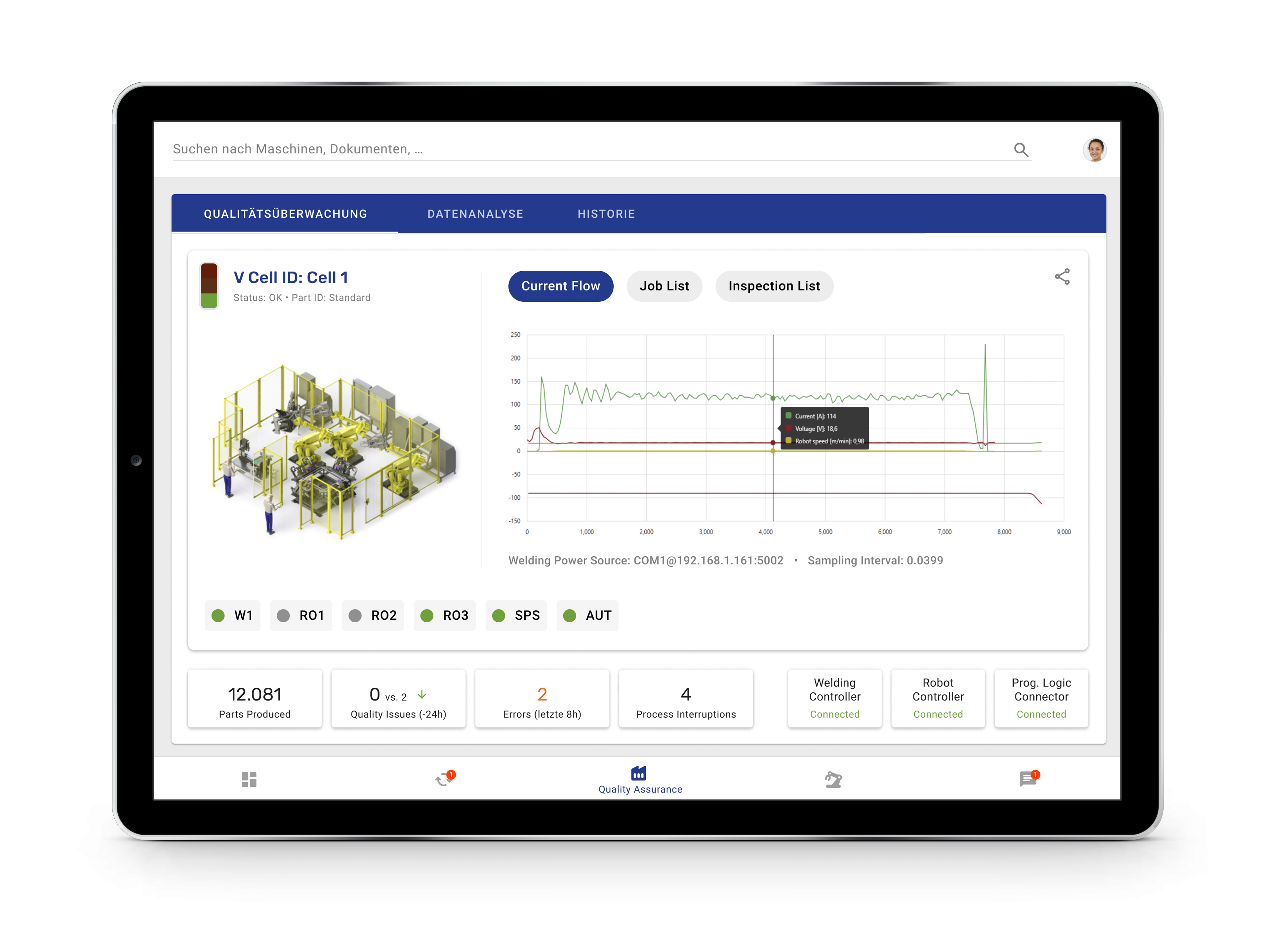

# Usecase – Autonomous Machine

IoT machine data combined with expert know-how determines predictive maintenance.

# Usecase – Increased Efficiency

Transparency across the machine life cycle and comprehensive networking expose inefficiencies

# Usecase – Data as a Service

Provision of your digital knowledge for any application or for your customers – Manufacturing X ready!

We develop digital service solutions specifically for medium-sized industrial companies

Your benefit is what drives us:

- Innovative service world around the machine

- Differentiation, new sales and cost reduction potential

- Customer proximity throughout the entire product life cycle

- We have been working exclusively for industry for 18 years

- We are software developers, technology consultants and strategic challengers

- We stand for success in the digital industry

Many industrial applications already anticipated

Industrial image processing

Robot Integration

Digital Machine File

Quality Control

Monitoring

Predictive Maintenance

Asset Management

Maintenance planning

Fieldbus Integration

… and more!

Our Approach

We work with our customers on a long-term and trusting basis

Definition of Service /

Factory Usecases

Definition Data and

Information model

Interface Implementation

Configuration KnowledgeHub

Operation by 247FactoryNet or Onpremis in the factory

Collect, refine and use data

We also manage the professional operation of your solution. Read more about our operation and service offering here.