The digital transformation in mechanical and plant engineering is here to stay

Digital transformation in mechanical engineering is much more than the use of digital technologies and digital data. Digital transformation describes a complete change in the established mechanics of the industry. Therefore, it requires a significant change from existing companies – only by doing so can today’s successful machinery and plant manufacturers survive in a digitally transformed industry.

The rules of the game are being rewritten and roles are being redistributed. Only those who adjust and adapt to this have a chance!

Digital transformation in mechanical engineering is much more than the use of digital technologies and digital data. Digital transformation describes a complete change in the established mechanics of the industry. Therefore, it requires a significant change from existing companies – only by doing so can today’s successful machinery and plant manufacturers survive in a digitally transformed industry.

The rules of the game are being rewritten and roles are being redistributed. Only those who adjust and adapt to this have a chance!

Digital transformation of production

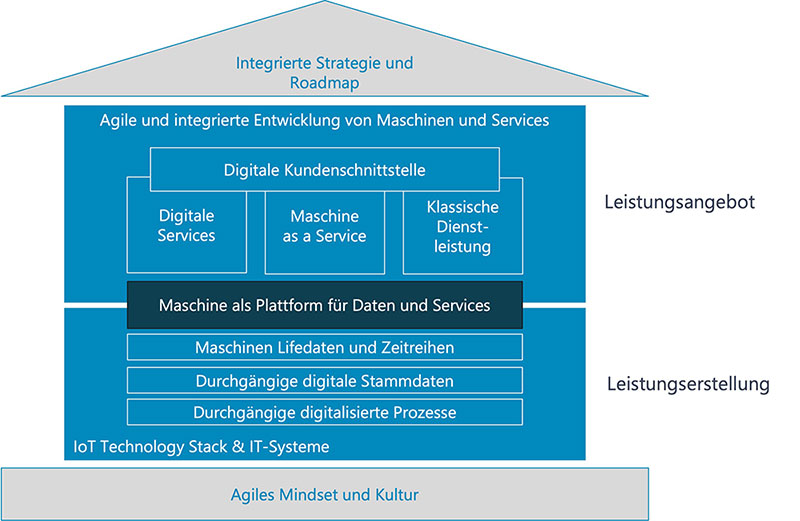

For companies in the mechanical and plant engineering sector, the digital transformation requires changes both in the area of the service offering for customers and in the area of internal service production. It is above all the diversity that makes the digital transformation of a company so complex and extensive. In addition to the actual design fields, topics such as new competencies, new ways of working and thinking, and high investments in IT play a role in the already strained skilled labor situation.

In our experience, the digital transformation of the factory goes hand in hand with the digital transformation of the range of services offered by machinery and plant manufacturers.

For companies in this sector, this means that you have to take a holistic view of the topic and first make strategic considerations for this.

The following design fields for digital transformation play together for machine and plant manufacturers:

Service orientation

New business models

New machine architecture

Digital data

Digital processes / digitalization of value creation

Digital mindset and agile ways of working

Machines produce data every day – it can be used to generate new value and new business.

We see more in your machine

In order to apply topics such as platform and data economics to future business in machine and plant engineering, the customer’s machine must be placed at the center of a lifecycle consideration. In the future, machines will no longer simply be sold. Instead, they will form the basis for service business that makes the operator of the machine better and also gives him the opportunity to adapt to new requirements from his business. This applies not only to standard machines, but just as much to digital transformation in plant engineering.

Internally, companies from the mechanical and plant engineering sector must therefore make significant structural and cultural changes. To this end, we not only offer technology know-how and software solutions. 247FactoryNet also supports its customers in the development of strategic visions of the future and in shaping the necessary agile organization.

247FactoryNet develops strategies with you for the digital transformation in mechanical engineering

Our model of a digitally transformed mechanical engineering company shows how a strategic future model can be structured.